-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Low Pressure Chemical Vapor Deposition LPCVD furnace system is the process of molecules moving from an area of high concentration to a low one. It occurs routinely within and between liquids, gases, and solids in daily life. This process is exploited by diffusion furnace, which elevate the temperature of work pieces and introduce gaseous elements to encourage solid state diffusion. Solid state diffusion occurs when molecules of a substance mix with a host solid at the atomic level. This mechanism of diffusion was a scientific curiosity for many years but has since become an integral process in semiconductor manufacturing.

We engineered a water-cooled diffusion furnace that can reach 1350°C in 10 minutes, as well as cool down below 800°C in a mere 2 minutes. Controlled graphene growth is ensured, and processing times are kept to a minimum with the Low Pressure Chemical Vapor Deposition LPCVD system. Various chamber tube sizes are available between Ø 2 in -- Ø 12 in allowing processing of single small samples up to batches in 6-inch wafers

Reactor Low Pressure Chemical Vapor Deposition LPCVD furnace system

Ø 50 mm-Ø 200 mm quartz tube chamber

Interchangeable Quartz tubes of various sizes as required

Accommodates Individual or multiple substrates up to 150 mm x 150 mm

Upstream end flange with quick connections to gas manifold

Downstream end flange with quick connections to pumping and gauging

Temperature/pressure control

The Low Pressure Chemical Vapor Deposition system features a single zone quartz lamp furnace with 6-inch uniform temperature zone

Auto-tuning feature provides very stable temperature control

Rapid heating to 1350°C in 10 minutes

Rapid cooling from 1350°C to 800°C in 2 minutes

Downstream pressure control 100mTorr to 500Torr using a throttling VAT butterfly valve

Up to 12 mass flow controllers

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

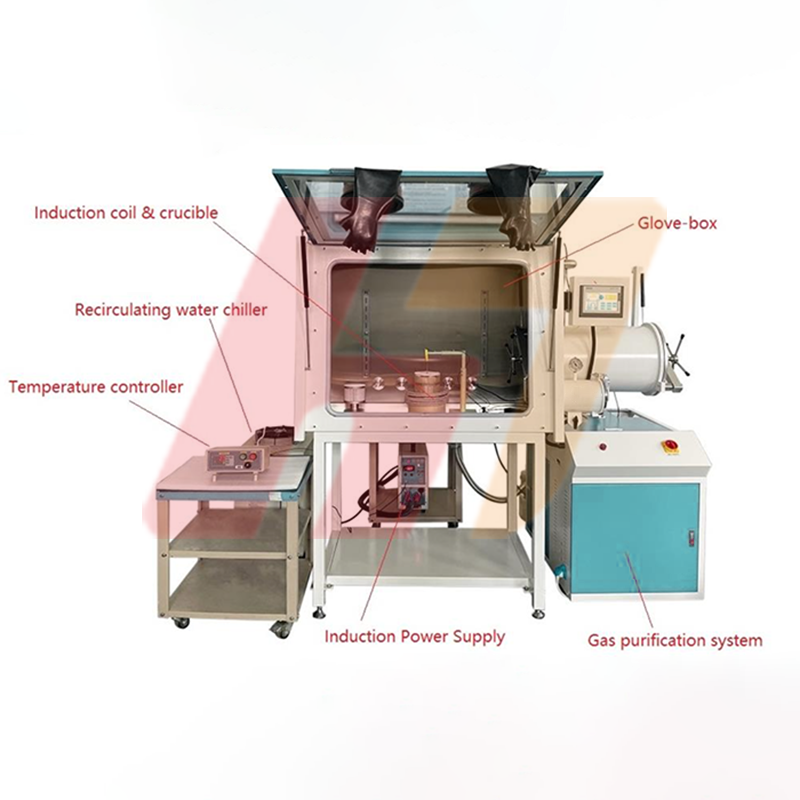

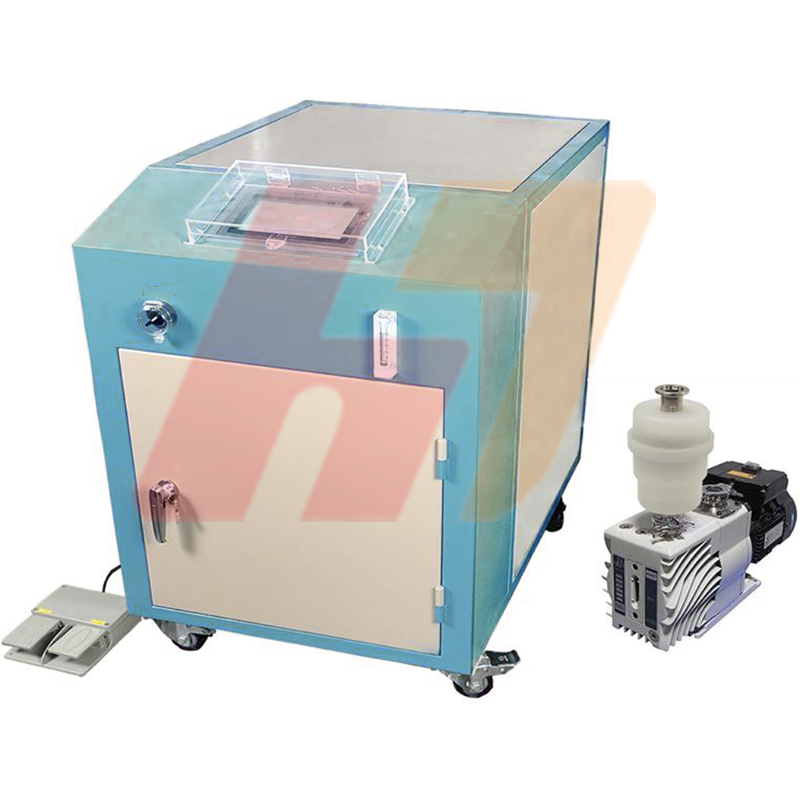

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut