-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Recently, a high-performance automatic circulation gas purification system made a stunning debut, bringing new solutions to numerous research and production fields.

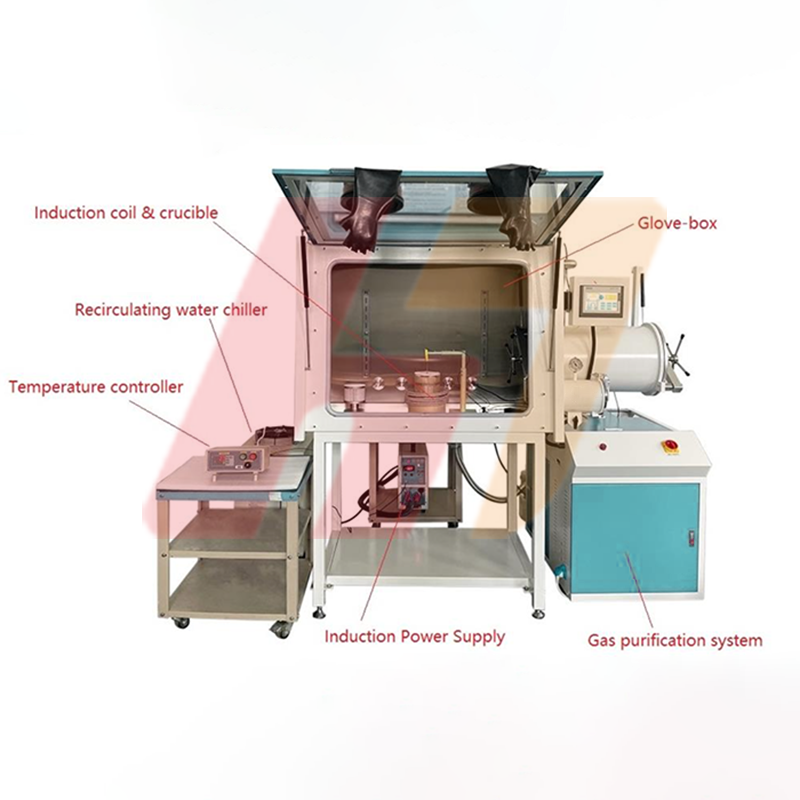

This automatic circulation gas purification system is specifically designed for glove boxes, which can strictly control the oxygen and moisture content inside the box to a very high standard of less than 1 ppm, providing reliable guarantee for experiments and production processes that require operation in an anhydrous and anaerobic environment.

Structurally, its casing is made of sturdy 304 stainless steel material with a thickness of 3mm, which not only has strong corrosion resistance but also excellent structural strength. The stainless steel wire drawing treatment on the inner surface and the spray coating process on the outer surface are both aesthetically pleasing and enh

ance the protective performance. The 8mm thick transparent tempered safety glass observation window installed on the box, combined with a solid core O-ring flange window structure, ensures no leakage while allowing operators to clearly observe the situation inside the box at any time.

The core part of the system - the circulating purification unit, the container is also made of 304 stainless steel. By using efficient purification materials such as copper catalysts and advanced purification technologies, the gas inside the box is continuously circulated and purified, efficiently removing trace amounts of active substances such as water and oxygen, and maintaining the ultra-high purity of the gas.

In terms of control system, the system has powerful functions, including self diagnosis, power-off self start characteristics, as well as pressure control and adaptive functions, which can achieve automatic and cyclic control, and are equipped with security measures such as password protection. The touch screen with its colorful Chinese and English operation interface allows operators to easily and conveniently access various functional modules, achieve intuitive human-machine dialogue, accurately monitor and operate the entire system, such as conveniently setting box pressure, purification parameters, etc.

In addition, the system is equipped with a vacuum pump that can be automatically turned on as needed to evacuate the transition chamber and maintain pressure balance in the box; Most water analyzers use phosphorus pentoxide sensors. The water probe is corrosion-resistant and can be restored to its initial state through a cleaning and regeneration program. It can be reused and reduces subsequent maintenance costs; Oxygen analyzers usually use zirconia sensors to avoid the problems of short lifespan and inability to be exposed to high oxygen environments in fuel cells (electrochemical cells), reducing the hassle of subsequent maintenance; The organic solvent adsorber can adsorb the volatile organic solvent atmosphere when the circulating gas first passes through, and can quickly replace the adsorbent material without damaging the high-purity atmosphere.

In practical applications, the gas purification system is closely integrated with equipment such as tube furnaces, glove boxes, and atmosphere sintering furnaces, playing an important role.

For tube furnaces, this high-purity gas environment ensures that material heat treatment, chemical reactions, and other processes carried out inside the tube furnace are not affected by oxygen and moisture interference, ensuring the accuracy of experimental results and the quality of materials. For example, in the synthesis and research of materials that require extremely high atmosphere, a pure gas environment can promote the smooth progress of the reaction and avoid the introduction of impurities that affect the performance of the product.

After being combined with the purification system, the glove box can provide a stable and reliable water and oxygen free space for operators to handle sensitive materials, conduct fine experiments or operations. Whether in the processing of electronic materials, the manufacturing of semiconductor devices, or the treatment of easily oxidized and hydrolyzed substances in chemical experiments, it can play an important role in ensuring that materials are not oxidized or dampened during the operation process, improving the success rate of experiments and product quality.

After applying this purification system, the atmosphere sintering furnace can accurately control the atmosphere during the sintering process, reducing the adverse effects of harmful components such as water, oxygen, and nitrogen on the product. For materials that are not suitable for using reducing or inert gases as a protective atmosphere, or are prone to decarburization and carburization, sintering in this high-purity atmosphere can effectively improve the performance and quality of the product. For example, in fields such as powder metallurgy and ceramic firing, denser and more uniform sintered bodies can be obtained, improving various performance indicators of the product.

In summary, this automatic circulation gas purification system provides critical high-purity gas environmental protection for equipment such as glove boxes, tube furnaces, and atmosphere sintering furnaces. It has broad application prospects and important practical value in many fields such as scientific research, electronics, materials, and chemical engineering, and will bring new assistance and breakthroughs to the development of related industries.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut