SG spiral type silicon carbide heating elements have the conventional central hot zone and two low resistivity cold ends. spiral SiC Heating Elements with unequal cold end length or with multiple hot zones can also be supplied if required.

Pledge: genuine guarantee,speed refund,gift insurance,seven days no reason to return

SG spiral type silicon carbide heating elements have the conventional central hot zone and two low resistivity cold ends. spiral SiC Heating Elements with unequal cold end length or with multiple hot zones can also be supplied if required. Elements are supplied as standard in one-piece construction, with no joints between the hot zone and the cold ends. The helical cut in the hot section increases the length and reduces the cross-section of the current path, forming a high resistance area, where most of the resistive heat is dissipated.

FEATURES of silicon carbide heating elements in high temperature furnace.

- Unparalleled resistance to oxidation and chemical attack.

- Excellent performance at element temperatures up to 1650°C.

- Repeatable and reliable results in the most aggressive high temperature processes.

SG type highest performance silicon carbide heating elements, designed to exceed the requirements of today's most demanding high temperature processes. With a porosity of less than half of conventional recrystallized silicon carbide heating elements, SG silicon carbide elements react much more slowly with the process atmosphere, whether this be oxidizing or reducing. This allows SG silicon carbide heating elements to be applied in equipment where conventional elements cannot be used, extends the element life, and permits the use of a less ex pensive electrical power supply.

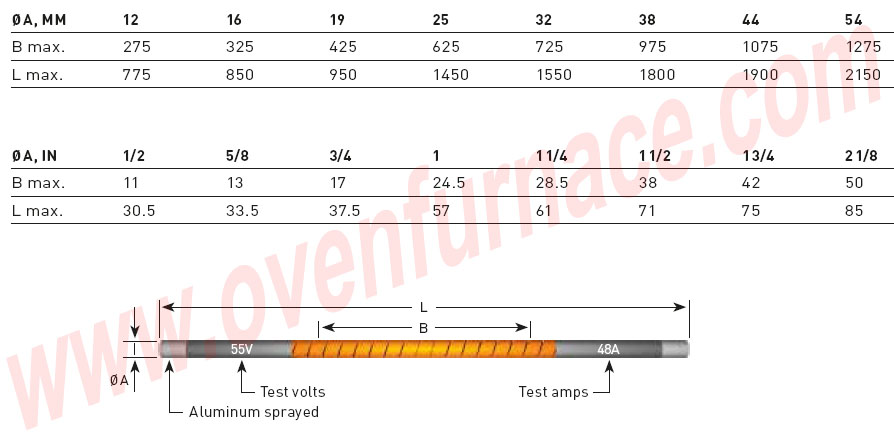

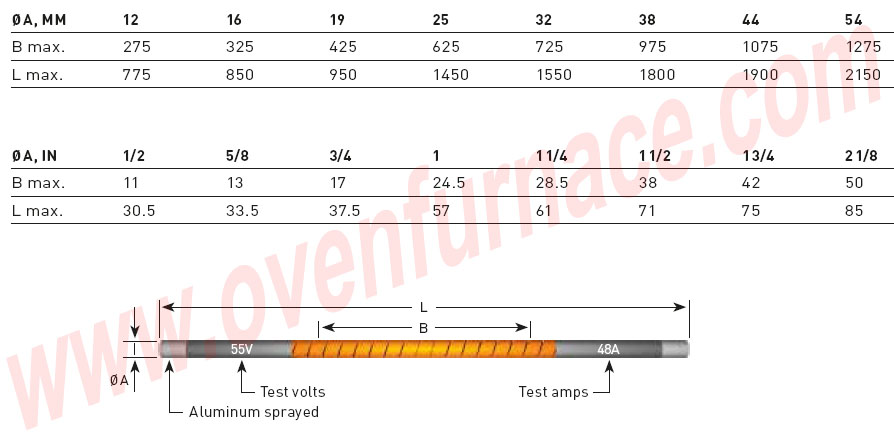

STANDARD DIMENSION of silicon carbide heating elements

SG spiral type silicon carbide heating elements have the conventional central hot zone and two low resistivity cold ends. spiral SiC Heating Elements with unequal cold end length or with multiple hot zones can also be supplied if required. Elements are supplied as standard in one-piece construction, with no joints between the hot zone and the cold ends. The helical cut in the hot section increases the length and reduces the cross-section of the current path, forming a high resistance area, where most of the resistive heat is dissipated.

FEATURES of silicon carbide heating elements in high temperature furnace.

- Unparalleled resistance to oxidation and chemical attack.

- Excellent performance at element temperatures up to 1650°C.

- Repeatable and reliable results in the most aggressive high temperature processes.

SG type highest performance silicon carbide heating elements, designed to exceed the requirements of today's most demanding high temperature processes. With a porosity of less than half of conventional recrystallized silicon carbide heating elements, SG silicon carbide elements react much more slowly with the process atmosphere, whether this be oxidizing or reducing. This allows SG silicon carbide heating elements to be applied in equipment where conventional elements cannot be used, extends the element life, and permits the use of a less ex pensive electrical power supply.

STANDARD DIMENSION of silicon carbide heating elements