-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Physical characteristics of sic heating elements

Characteristics Items | Unit | Type D | Type E&F | Type SG&SGR |

Pretension Density | 3.2 | 3.2 | 3.1 | |

Bulk Density | 2.8 | 2.8 | 2.8 | |

Apparent Porosity | % | 23 | 23 | 5 |

Bending Strength | MPa at 25°C | 49 | 49 | 98 |

Specific Heat | kJ/kg+°C at 25°C~1300°C | 1.0 | 1.0 | 1.0 |

Heat Conductivity | W/m +°C at 1000°C | 14~19 | 14~19 | 16~21 |

Nominal Resistance | Ω cm at 1000°C | 0.10 | 0.08 0.10 | 0.016 |

Coefficient of Thermal Expansion | 1000°C(X10-6/°C) | 4.5 | 4.5 | 4.5 |

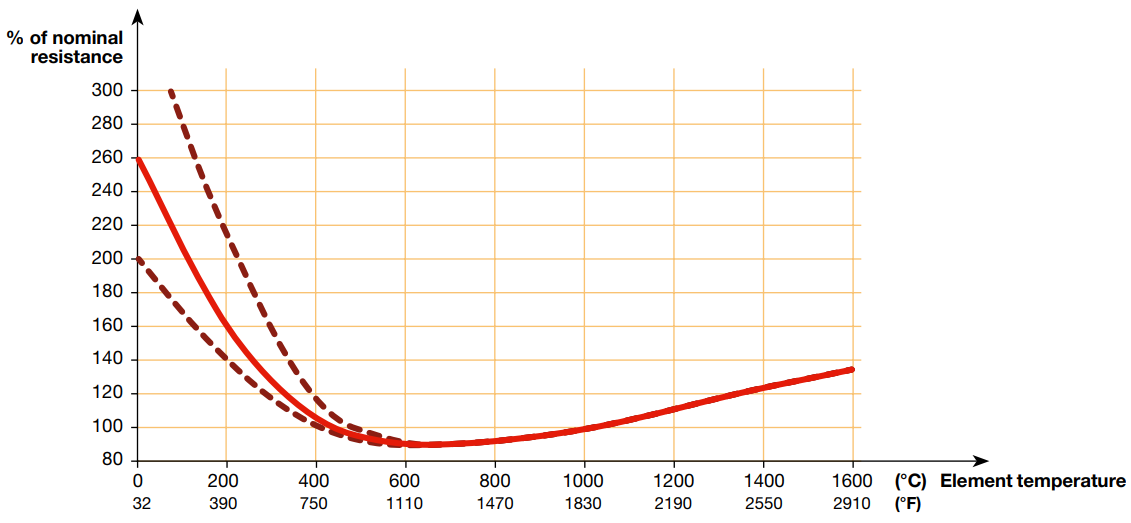

Typical resistance temperature of sic heating elements

As shown in Fig.1, the temperature coefficient of STA resistance-temperature characteristics is negative up to 650°C to 700°C (When the temperature goes up, the resistance value goes down). Then, when it exceeds that temperature, it becomes positive (When the temperature goes up, the resistance value goes up.).

Note. The STA SiC resistance is usually measured at 1000°C in open air and the nominal resistance differs extremely from that measured at room temperature. (Refer to Fig. 1)

Chemical characteristics of sic heating elements

The STA SiC heating elements are made of chemically stable silicon carbide with high purity and are superior to metal heating elements in terms of high temperature stability, oxidation resistance and corrosion resistance. When the silicon carbide heating elements are operated at high temperatures, they come into contact and react with a gas atmosphere such as vapor, hydrogen, nitrogen, sulfur, halogen, etc., molten alkali, alkaline salts (K2CO3, KCl, KOH, NaF, etc.), molten metals (Fe, Ni, Co, etc.), and some metal oxides (CuO, Pb3O4, FeO, etc.), and will be affected by erosion or oxidation when the above reactions occur.

When STA SiC heating elements are handled in a gas atmosphere, refer to "Effects of Atmosphere Condition on STA SiC Heating Elements." In designing a furnace, when the above corrosive substances by which STA is affected are involved, caution must be exercised to avoid any direct contact by STA.

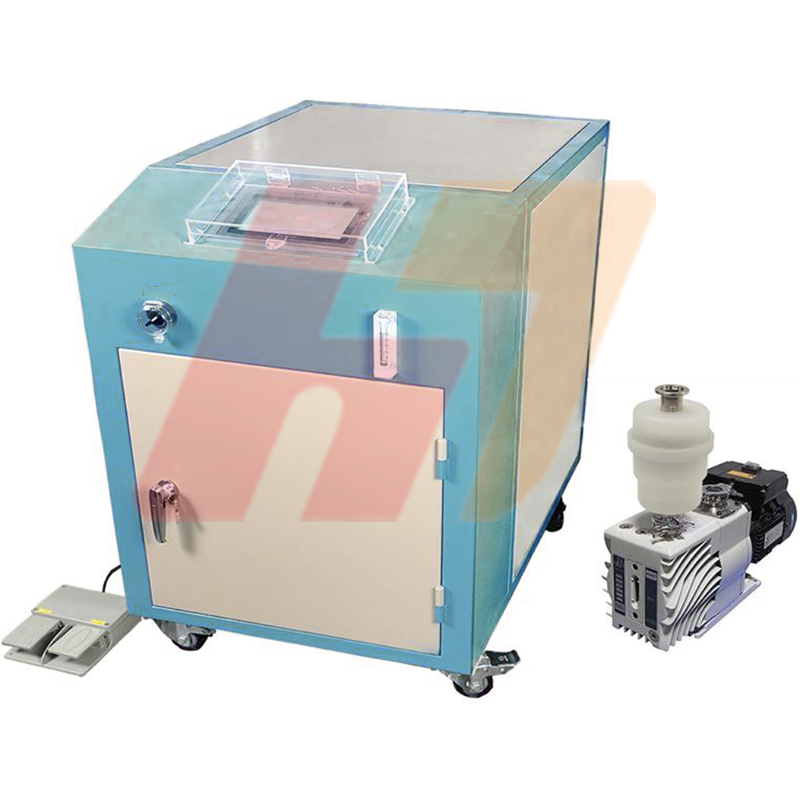

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

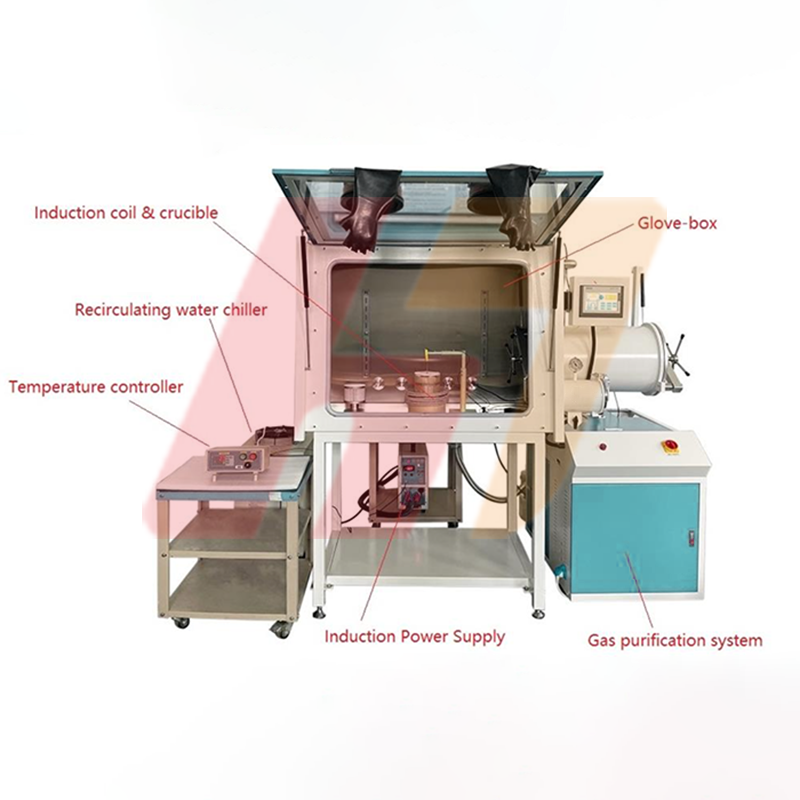

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut