-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

It is very important that the tubes and flanges installed on furnaces are set up and utilized properly. Having the necessary knowledge on their capabilities and functions will allow the user to perform experimentations under the most ideal conditions and attain the best possible results. This also ensures that the longevity of the furnace components is best preserved.

Different kinds of tubes have different characteristics that possess their own inherent limitations. This guide aims at providing existing and prospective users the basic knowledge necessary for properly utilizing and maintaining the tubes. It also serves to help the users to understand the characteristics of each tube type and the extent of their capabilities.

TUBES

Below are some basic properties of the two most common types of tubes used on STA’s line of tube furnaces. Please take time to get familiarized with their characteristics and use them accordingly.

ATTENTION:

Tubes are consumable parts that are not covered by STA’s one year limited warranty. It is the end user’s responsibility to be cognizant of their properties in order to ensure their full utilization with the utmost safety.

Quartz:

Transparent color

Max. Temperature: 1200

Excellent resistance to thermal shock; offers maximum versatility with all furnaces’ heating and cooling rates

Can be used under vacuum conditions at all temperature settings

Alumina:

Beige color

Max. Temperature: 1800

Susceptible to thermal shock; heating and cooling rates must not exceed 5C/min when temperature is above 1500 ºC

to prevent tube from cracking

The tube gets softened when temperature is greater than 1500 ºC. Use of vacuum above this temperature is strictly prohibited as the vacuum will cause the tube to collapse when it becomes softened.

SETTING UP THE TUBE AND VACUUM FLANGES for tube furnace.

Properly setting up the tube and vacuum flanges prior to heating will ensure the furnace to work under the most ideal conditions. This will insulate the heat from the flanges while simultaneously preventing the dissipation of heat from the furnace chamber. The insulation of heat stabilizes the heating zone which in turn expends less energy and places less wear on the heating elements.

Please use the tips below for safe and proper handling of the tube furnace equipment.

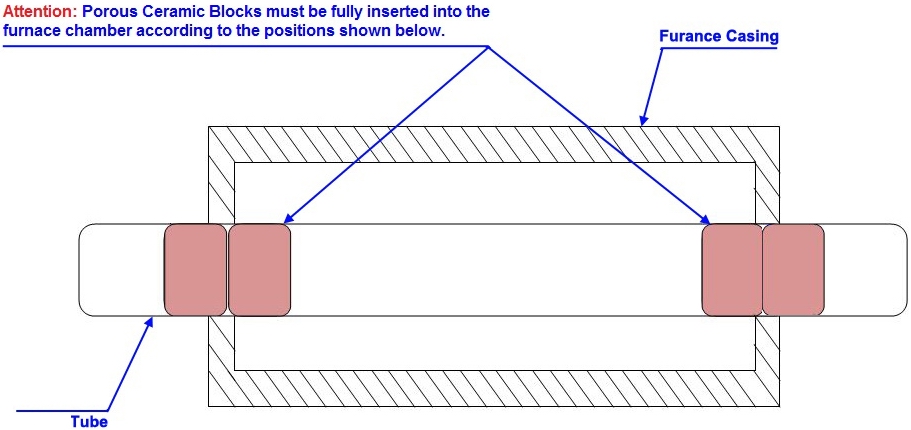

1. Refractory tube blocks should ALWAYS be inserted inside the tube and placed on both ends of the furnace casing (shown in the picture below).

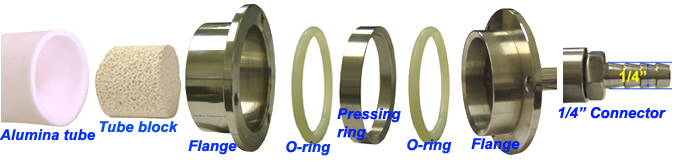

2. Install the vacuum sealing flanges on each side of the tube using the picture below as reference. Seal the flanges by tightening the screws to finish the assembly.

3. Limit the pressure regulator attached to the gas tank to below 1.1 atm before filling the tube with gas. Keep the vacuum valve(s) open during gas filling to avoid high pressure from building up inside tube.

WARNING:

Tube furnaces are designed to be used under vacuum with low pressure gases. NEVER inject gas into the tube with pressure higher than 1.1 atm. Pressure build up inside the tube may cause the flange(s) to be catapulted which may cause injury or death.

Use of vacuum on alumina tubes at temperatures over 1500 ºC is strictly prohibited.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

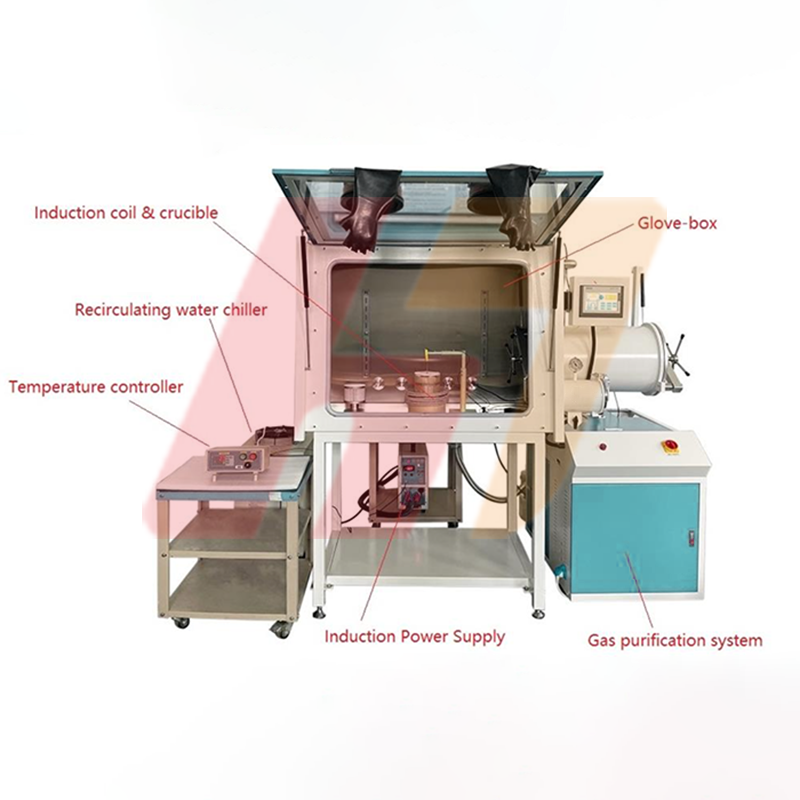

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

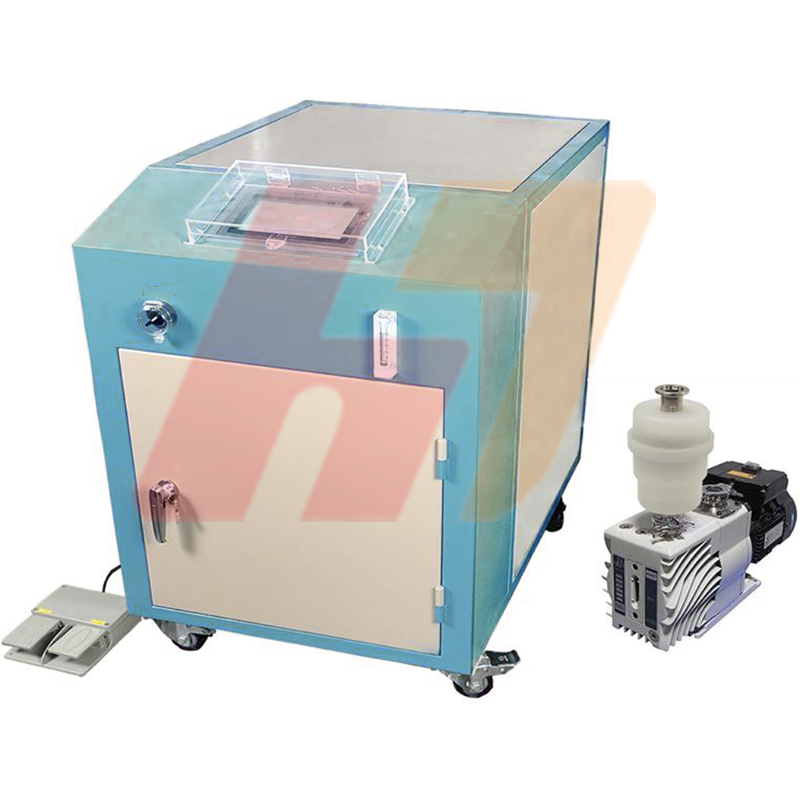

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut