-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Silicon carbide heater can be used in the furnaces with different atmosphere, however, service life of Silicon carbide heating elements will be affected and shortened under some atmospheres. In order to extend the service life of silicon carbide heater in different atmospheres, we developed various coating to protect the SiC structure of heater to prevent rapid aging, the coatings we have mainly are A Coating, B Coating, D Coating. But actually, several harmful volatiles possibly exist in some furnaces meanwhile, and even some harmless volatiles become harmful after mixed with some other volatiles, thereby affecting the service life of heater. Since different coatings have different effects in different atmospheres, it’s necessary to proceed the small batch tests against the specific problem in order to find out the optimum plan and select the best coating.

Different environment of coating of silicon carbide heater

Atmosphere | Effect | Solution | Recommend Coat |

Vapor and Moisture | Service life shortened 20% than in dry air | New furnace or old furnaces not work long time, to dry at low temperature completely and then heat up | A coat |

Nitrogen gas | Above 1400℃, nitrogen will react with SiC to form silicon nitride, elements will become fragile and service life shortened. The effect by dew point is same as H2 | The recommended furnace temperature not higher than 1300℃, surface loading as low as possible | B coat |

Hydrogen | The mechanical strength decreasing when elements temperature exceeds 1350℃, and also service life much depends on intensity of moisture. | Operation temperature lower than 1300℃, surface loading less than 5W/ CM2 | |

Ammonia | Same as hydrogen and nitrogen | Operation temperature lower than 1300℃, surface loading less than 5W/ CM2 | B coat |

Disassociated gas (Mixture of N2,CO,CO2,H2,CH4) | Carbon black from decomposed hydrocarbon on elements surface will cause silicon carbide heater loose. | Introducing air into furnace frequently to burn up additional Carbon. At side of furnace design, keep enough space between elements to prevent short circuit. | |

(S、S2) | Above 1300℃, surface of elements will be corroded and resistance increasing rapidly. | Keep silicon carbide heating elements temperature lower than 1300℃ | |

Vacuum | SiO2 protect film will not be formed, SiC decomposed itself and service life shortened. | Using in pressure over 0.13Pa and furnace temperature under 1100℃ | |

Others | Various substances from treated materials, such as Pb, Sb, alkali metal react with elements, which may shorten elements service life. | To get rid of these substances in advance, design gas outlet in furnace in order to decrease the effect. | C coat |

If you any requirement for silicon carbide heater, please free contact with us. We must give you a best solution ways for you high temperature furnace.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

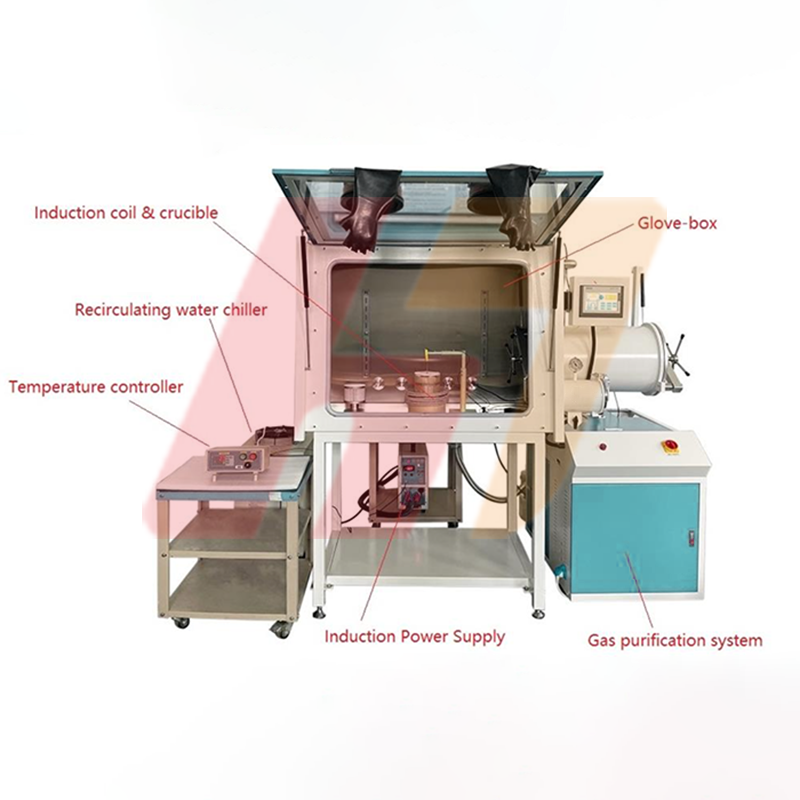

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

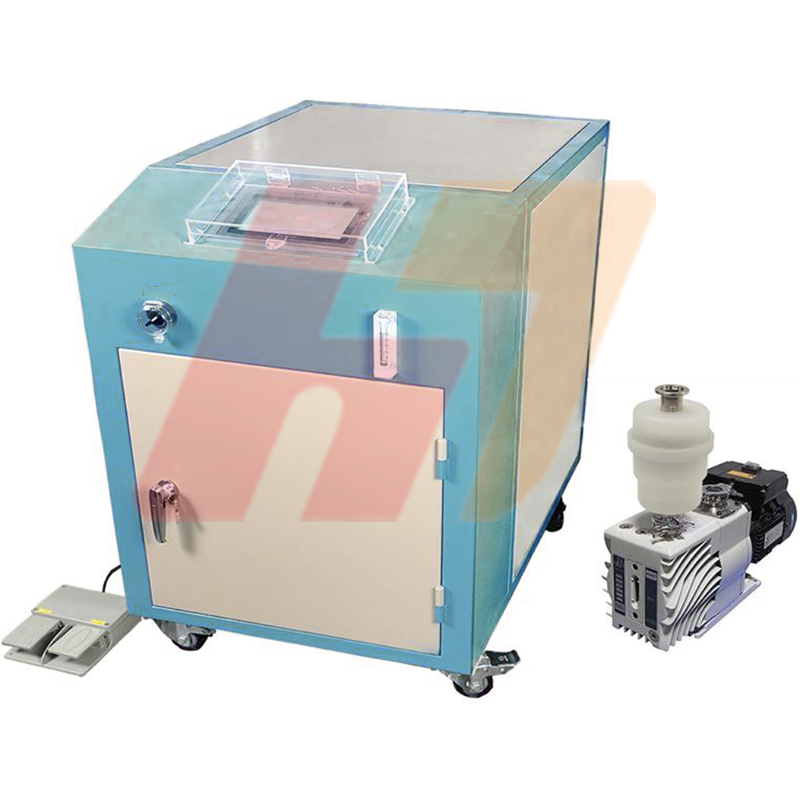

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut