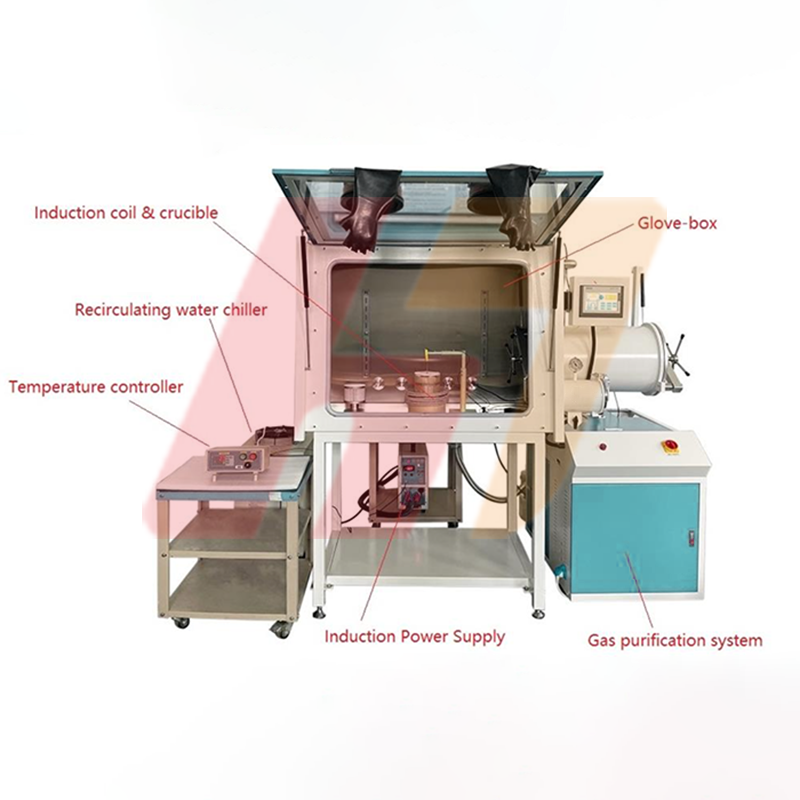

This is an induction meting system in the standard glovebox with gas purification (O2 & H2O < 1 PPM) and a programmable temperature controller. It is excellent for melting air-sensitive alloys, such as Al, Mg, and Li, etc. Its melting temperature range can reach from 750ºC to 1700ºC by choosing different induction power supplies and thermal couples.

This is an induction meting system in the standard glovebox with gas purification (O2 & H2O < 1 PPM) and a programmable temperature controller. It is excellent for melting air-sensitive alloys, such as Al, Mg, and Li, etc. Its melting temperature range can reach from 750ºC to 1700ºC by choosing different induction power supplies and thermal couples.

Induction Melting System equipped with digital display in Glovebox with Gas Purification (1PPM) is a highly specialized equipment combination.

Among them, the induction melting system utilizes the principle of electromagnetic induction to generate eddy currents inside the heated metal through specific power output (such as adjustable within the range of 10kW-50kW) and frequency range (such as 10kHz-50kHz), thereby quickly and uniformly heating and melting. Accurate temperature control (within the range of 500 ℃ -2500 ℃, with temperature fluctuations not exceeding ± 5 ℃) ensures the stability of the melting process and high-quality melting products.

The glove box provides a closed environment for the entire smelting operation. It is like a protective cover, preventing external dust, moisture, and oxygen from entering, creating a relatively independent and controllable operating space for induction melting. Its specific dimensions (such as 120 centimeters long, 80 centimeters wide, and 100 centimeters high) and high-strength stainless steel material ensure spacious interior space, easy operation and equipment maintenance, as well as excellent corrosion resistance and mechanical strength. Equipped with a transparent tempered glass operating window with a diameter of 30 centimeters, it is convenient for operators to clearly observe the internal operation situation.

The gas purification system is the key to ensuring high purity in the smelting environment. Through multi-stage filtration techniques such as activated carbon filtration to remove organic impurities and odors, molecular sieve filtration to remove moisture and oxygen, and high-efficiency filters to remove small particles and bacteria, the gas impurities inside the glove box are reduced to a level of one part per million (1PPM). This can ensure that the material is not contaminated by impurities in the gas during the smelting process, thereby obtaining high-purity smelting products. Purification flow rate (such as 10L/min -50L/min) can quickly purify the gas inside the glove box, ensuring that the gas remains in a high-purity state at all times. The various parts of the entire system work together to provide reliable support for high-quality induction melting.

Specifications:

Induction Heaters | Two options of induction power supply 80KHz, 7KW, 208- 240VAC, 50/60 Hz, single-phase, for max working temperature of 1200ºC 80KHz, 15KW, 208- 240VAC, 50/60 Hz, three-phase, for max working temperature of 2200ºC |

Glovebox | Glovebox Case is made of stainless steel 304 with 3 mm thickness Chamber dimension: 1200 mm L x 740 mm W x 900 mm H Openable front window panel (tempered glass, 8 mm thick) Gas purification system with automatic purging and regeneration function Gas purification: O2 < 1 ppm and H2O < 1 ppm |

Induction Coil & Crucible | Water cold Induction coil with 200 mm ID is placed inside the glovebox via feedthrough Graphite crucible with the dimension of φ114 OD x φ100 ID x 142 H (mm) is included A thermal couple with a support fixture is included for controlling the melting temperature 5" OD Quartz tube chamber is available for vacuum function at the extra cost K type T/C for 750ºC - 1200ºC B type T/C for 1200ºC - 1700ºC C type T/C for > 1700ºC , up to 2200ºC |

Temperature Controller | Precision digital temperature controller with Automatic PID tuning 30 segments programmable for controlling heating and cooling rate as well as dwell time Overheating & thermocouple failure protection +/- 2 ºC temperature accuracy One the thermal couple is included and T/C type is dependent on max. melting temperature |

Water Chiller | Temperature range: 5 - 30°C Water Flow Rate: 58 L/min Water Tank: 15 Liters made of stainless steel Note: It is recommended to use a specific coolant to get the best performance. It is normal to wait a couple of minutes for cooling down after several trials of heating Note: the input voltage for the water chiller is 220V |

Warranty | One year limited warranty with lifetime support Consumable parts such as processing tubes, o-rings, and heating coil are not covered by the warranty |

Note:All products can be customized. If you need more products, please go to our official website homepage.

Besides, HengTong furnace range include, laboratory muffle furnace, vacuum tube furnace, dental zirconia sintering furnace, atmosphere furnace, vacuum furnace, crucible furnace, box chamber furnace, bottom loading furnace, bogie hearth furnace.

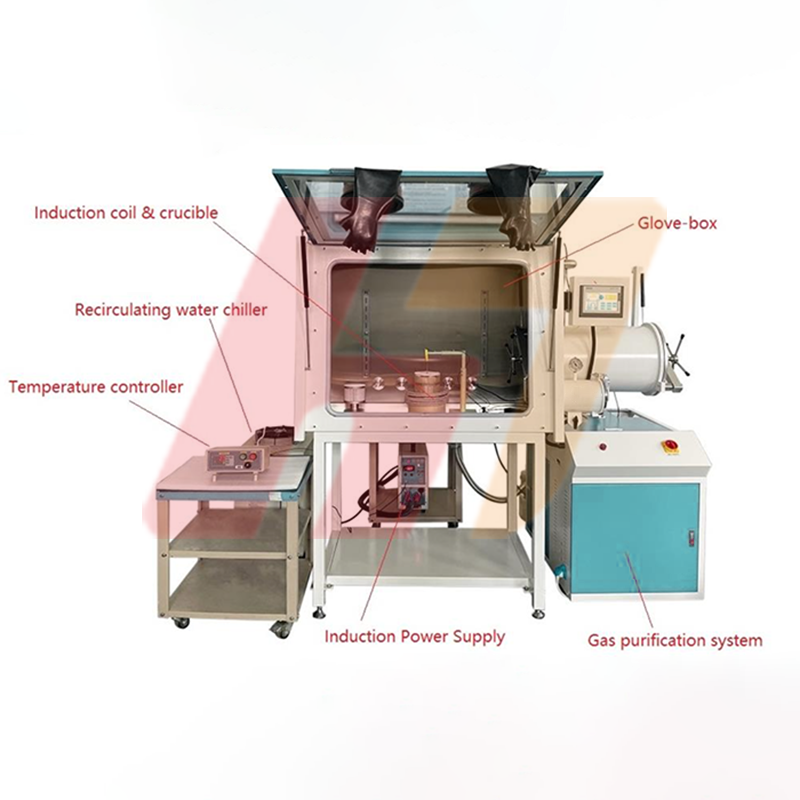

This is an induction meting system in the standard glovebox with gas purification (O2 & H2O < 1 PPM) and a programmable temperature controller. It is excellent for melting air-sensitive alloys, such as Al, Mg, and Li, etc. Its melting temperature range can reach from 750ºC to 1700ºC by choosing different induction power supplies and thermal couples.

Induction Melting System equipped with digital display in Glovebox with Gas Purification (1PPM) is a highly specialized equipment combination.

Among them, the induction melting system utilizes the principle of electromagnetic induction to generate eddy currents inside the heated metal through specific power output (such as adjustable within the range of 10kW-50kW) and frequency range (such as 10kHz-50kHz), thereby quickly and uniformly heating and melting. Accurate temperature control (within the range of 500 ℃ -2500 ℃, with temperature fluctuations not exceeding ± 5 ℃) ensures the stability of the melting process and high-quality melting products.

The glove box provides a closed environment for the entire smelting operation. It is like a protective cover, preventing external dust, moisture, and oxygen from entering, creating a relatively independent and controllable operating space for induction melting. Its specific dimensions (such as 120 centimeters long, 80 centimeters wide, and 100 centimeters high) and high-strength stainless steel material ensure spacious interior space, easy operation and equipment maintenance, as well as excellent corrosion resistance and mechanical strength. Equipped with a transparent tempered glass operating window with a diameter of 30 centimeters, it is convenient for operators to clearly observe the internal operation situation.

The gas purification system is the key to ensuring high purity in the smelting environment. Through multi-stage filtration techniques such as activated carbon filtration to remove organic impurities and odors, molecular sieve filtration to remove moisture and oxygen, and high-efficiency filters to remove small particles and bacteria, the gas impurities inside the glove box are reduced to a level of one part per million (1PPM). This can ensure that the material is not contaminated by impurities in the gas during the smelting process, thereby obtaining high-purity smelting products. Purification flow rate (such as 10L/min -50L/min) can quickly purify the gas inside the glove box, ensuring that the gas remains in a high-purity state at all times. The various parts of the entire system work together to provide reliable support for high-quality induction melting.

Specifications:

Induction Heaters | Two options of induction power supply 80KHz, 7KW, 208- 240VAC, 50/60 Hz, single-phase, for max working temperature of 1200ºC 80KHz, 15KW, 208- 240VAC, 50/60 Hz, three-phase, for max working temperature of 2200ºC |

Glovebox | Glovebox Case is made of stainless steel 304 with 3 mm thickness Chamber dimension: 1200 mm L x 740 mm W x 900 mm H Openable front window panel (tempered glass, 8 mm thick) Gas purification system with automatic purging and regeneration function Gas purification: O2 < 1 ppm and H2O < 1 ppm |

Induction Coil & Crucible | Water cold Induction coil with 200 mm ID is placed inside the glovebox via feedthrough Graphite crucible with the dimension of φ114 OD x φ100 ID x 142 H (mm) is included A thermal couple with a support fixture is included for controlling the melting temperature 5" OD Quartz tube chamber is available for vacuum function at the extra cost K type T/C for 750ºC - 1200ºC B type T/C for 1200ºC - 1700ºC C type T/C for > 1700ºC , up to 2200ºC |

Temperature Controller | Precision digital temperature controller with Automatic PID tuning 30 segments programmable for controlling heating and cooling rate as well as dwell time Overheating & thermocouple failure protection +/- 2 ºC temperature accuracy One the thermal couple is included and T/C type is dependent on max. melting temperature |

Water Chiller | Temperature range: 5 - 30°C Water Flow Rate: 58 L/min Water Tank: 15 Liters made of stainless steel Note: It is recommended to use a specific coolant to get the best performance. It is normal to wait a couple of minutes for cooling down after several trials of heating Note: the input voltage for the water chiller is 220V |

Warranty | One year limited warranty with lifetime support Consumable parts such as processing tubes, o-rings, and heating coil are not covered by the warranty |

Note:All products can be customized. If you need more products, please go to our official website homepage.

Besides, HengTong furnace range include, laboratory muffle furnace, vacuum tube furnace, dental zirconia sintering furnace, atmosphere furnace, vacuum furnace, crucible furnace, box chamber furnace, bottom loading furnace, bogie hearth furnace.