-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

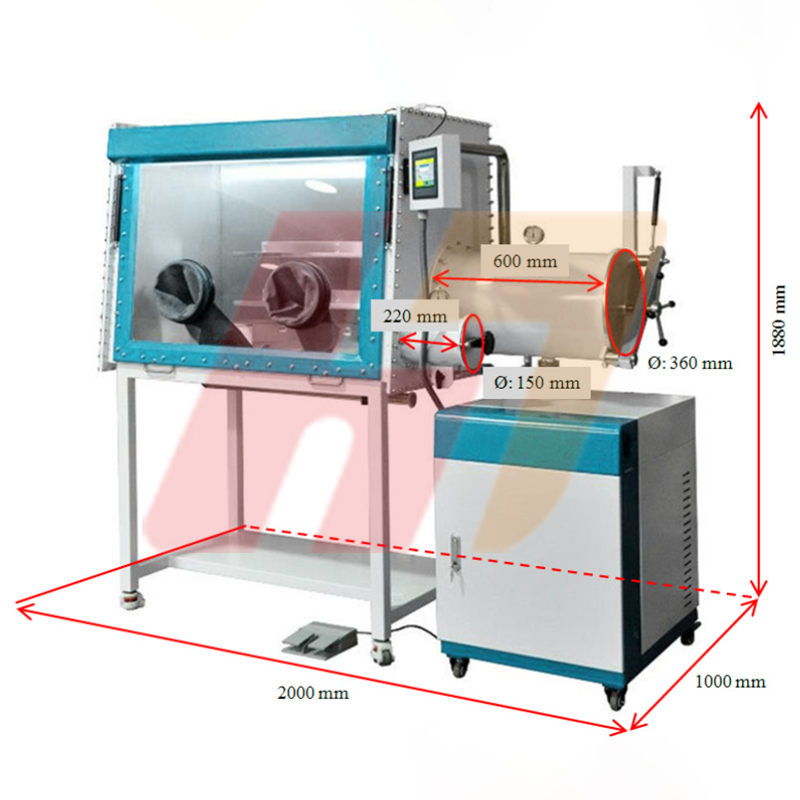

This glove box is usually made of sturdy and durable materials, such as high-strength stainless steel or aluminum alloy, to ensure its stable performance in various environments. The appearance design is simple and elegant, and the size can be selected according to different usage needs. One of its prominent features is the hinged front window, which is usually made of high-strength transparent materials such as tempered glass or polycarbonate, ensuring good visibility and withstanding certain pressure and impact.

There are many applications in many fields, such as experiments in chemistry, physics, materials science, etc., for processing samples sensitive to water and oxygen. For example, in the process of synthesizing certain special materials and conducting precise chemical reactions, it is necessary to strictly control the content of water and oxygen.

Provide stable operating space for experiments that require specific environmental conditions, such as low-temperature experiments, high-pressure experiments, etc.

During the assembly and production process of electronic components, prevent water and oxygen from causing damage to sensitive electronic components. For example, in the manufacturing of semiconductor devices, low water and low oxygen environments can improve product quality and reliability.

Some are used for packaging, testing, and other operations on electronic components to ensure a clean operating environment.

In the pharmaceutical industry's drug production and research and development process, ensure a sterile, low water, and low oxygen operating environment to prevent drug contamination. Used for packaging, storage, and other processes of drugs to ensure their quality and stability.

HengTong furnace range include, laboratory muffle furnace, vacuum tube furnace, dental zirconia sinting furnace, atmosphere furnace, vacuum furnace, crucible furnace, box chamber furnace, bottom loading furnace, bogie hearth furnace.&The temperature of Hengtong laboratory and industrial furnaces and ovens are ranging from 200 °C to 1800 °C.

Significant features:

1.Water and oxygen purification system

Purification components and principles:

Adsorbent: High efficiency adsorbent materials such as molecular sieves are usually used to remove moisture. Molecular sieves have a rich microporous structure that can strongly adsorb water molecules, ensuring that the humidity inside the glove box is maintained at an extremely low level. For the removal of oxygen, palladium catalysts may be used to promote the reaction between oxygen and hydrogen to generate water, thereby reducing the oxygen content.

Catalytic components: In the process of oxygen purification, catalytic components play a crucial role. For example, palladium catalysts can accelerate the reaction between oxygen and hydrogen under specific conditions, improving purification efficiency.

Gas circulation device: Through the built-in gas circulation system, the gas inside the glove box is continuously circulated through the purification element to ensure the continuous and stable purification effect.

Purification effect and advantages:

Efficient purification: It can reduce the moisture content in the glove box to extremely low ppm levels, and the oxygen content can also be controlled within a very low range, providing an ideal environment for experiments and operations that are sensitive to water and oxygen.

Stable and reliable: The purification system has been carefully designed and optimized to maintain stable purification effects over long periods of operation, reducing the impact of environmental factors on experimental results.

2.Hinged front window

Material and Structure:

Window frame material: Generally, high-strength metal materials such as stainless steel or aluminum alloy are used to ensure the robustness and stability of the structure. These materials have good corrosion resistance and mechanical strength, can withstand frequent opening and closing operations, and ensure long-term use without deformation.

Glass material: The front window is usually made of high-strength transparent materials, such as tempered glass or polycarbonate. Tempered glass has high strength and impact resistance, and is not easily broken even in unexpected situations. Polycarbonate has the advantages of light weight and good corrosion resistance.

Sealing structure: In order to ensure the sealing performance when the front window is closed, high-quality rubber sealing rings or sealants are usually used. These sealing materials can effectively prevent external air and impurities from entering the glove box, ensuring the purity of the internal environment.

Operational convenience and observability:

Opening method: The hinged design allows the front window to be easily opened and closed, making operation convenient and fast. The opening angle can be adjusted according to actual needs, making it convenient for operators to access and operate items.

Observation effect: The transparent front window provides a good observation field, allowing operators to clearly observe the experimental or operational situation inside the glove box, timely grasp the progress and make adjustments.

3.Overall material and manufacturing process

Box material:

Main material: The box body of the glove box is usually made of high-strength stainless steel or aluminum alloy sheet. These materials have good corrosion resistance, mechanical strength, and sealing properties, which can effectively isolate the external environment and provide a stable working environment for the interior.

Surface treatment: In order to improve the corrosion resistance and aesthetics of the box, surface treatment is usually carried out, such as spraying anti-corrosion paint, anodizing, etc. These processing methods can enhance the surface hardness and corrosion resistance of materials, extending the service life of glove boxes.

Glove material:

Rubber gloves: generally made of chemically resistant and highly elastic rubber materials. This type of glove can tightly fit the operator's hands, providing good operational flexibility and sealing. Meanwhile, rubber gloves have good chemical corrosion resistance and can be used in various chemical environments.

Silicone gloves: Silicone gloves are also a common choice. Silicone has excellent high and low temperature resistance and chemical stability, and can be used in a wider range of temperature and chemical environments. In addition, silicone gloves have excellent softness and elasticity, providing a comfortable operating experience.

Manufacturing process:

Precision welding: The welding process of the box adopts precision welding technology to ensure the sealing and strength of the weld seam. Strictly control welding parameters during the welding process to ensure welding quality and prevent defects such as missed welding and porosity.

Sealing treatment: Strict sealing treatment is carried out at various connection parts and interfaces of the box. Using high-quality sealing materials and sealing processes to ensure the overall sealing of the glove box, preventing the infiltration of external air and impurities.

In short, the glove box with water and oxygen purification system and hinged front window provides reliable protection for various experiments and operations with strict environmental requirements, thanks to its advanced purification system, high-quality materials, and exquisite manufacturing technology.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

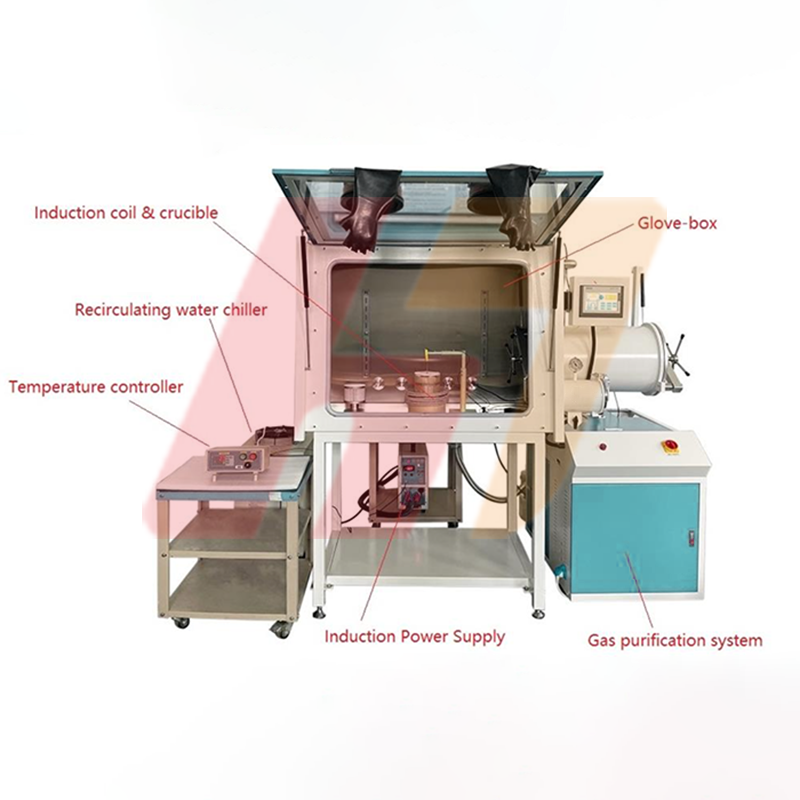

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

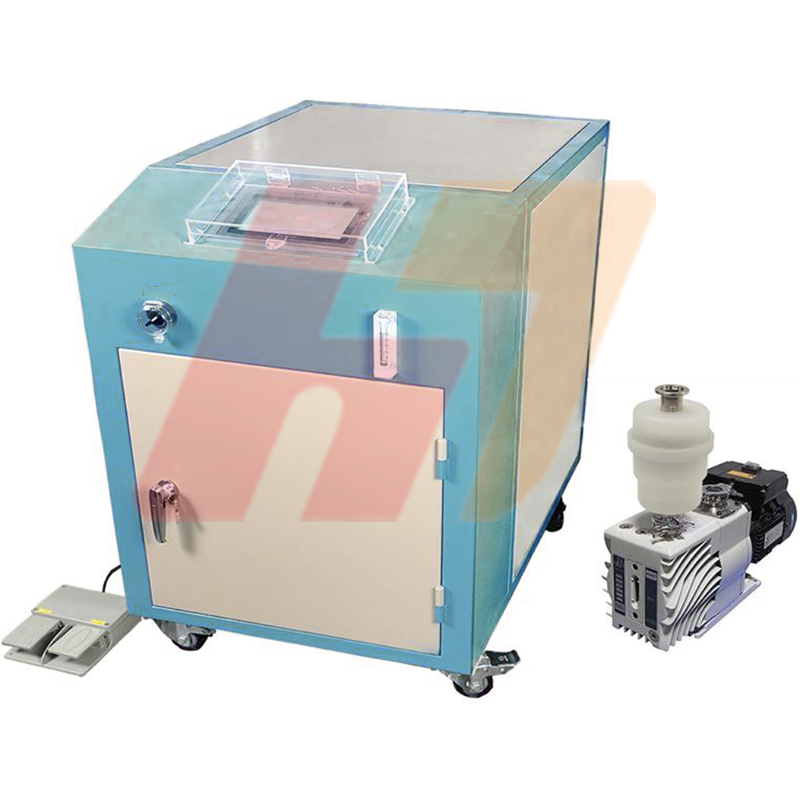

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut