-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Vacuum rotating tube furnace are used for continuous heat treatment of small sample volumes (approx. 1 l to 10 l) of powders or granulates, also under inert gas (e.g. calcinations). HT Rotary tube furnace with new 3 zone split tube furnace has a maximum operating temperature of 1150 °C and is based on the reliable model HT1200-R. The three heating zones have an overall heating length of 900 mm. The vacuum tube furnace frame can be easily adjusted between horizontal and approximately 10° of incline. Variable tilt and rotation speeds result in highly flexible residence times. Wire elements in high quality vacuum formed insulation ensure fast heat up, excellent temperature uniformity and short cool down times.

Operation of vacuum rotating tube furnace is user-friendly and safe. The work tube is easily removed by opening this split vacuum tube furnace, which also allows easy access e.g. for cleaning. A safety switch automatically stops the tube from rotating and interrupts the power supply for the heating elements.

The sample is automatically fed into the rotating tube furnace via a RETSCH vibratory feeder and recovered in a 5 liter collecting vessel after the heat treatment process is finished.

Benefits at a Vacuum rotating tube furnace

1150 °C maximum operating temperature

Heating length of 900 mm

3 zone temperature control

Work tube with outer diameters up to 110 mm

Inert gas package available on request

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

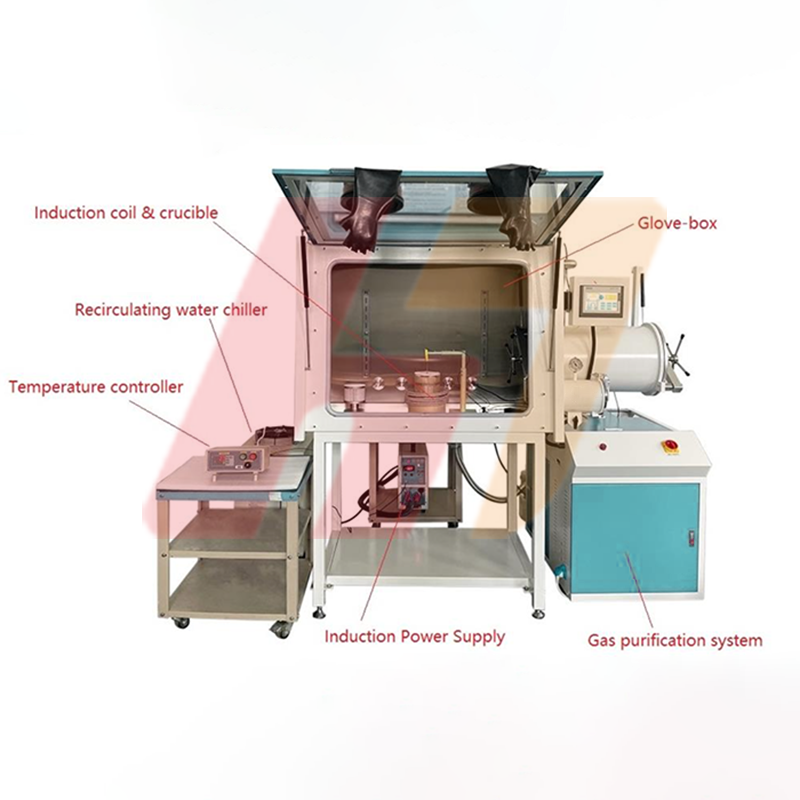

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut